Cartridge Heater - Benefits Accross Various Industries

In today's rapidly evolving industrial landscape, the demand for efficient heating solutions is higher than ever before. Industries across the board require precise and reliable methods for heating liquids, gases, and even solid materials for various processes. Among the array of heating solutions available, one technology that stands out for its versatility and effectiveness is the Cartridge Heater. These heaters have become an indispensable tool for industries, providing exceptional thermal performance and adaptability to meet diverse heating needs.

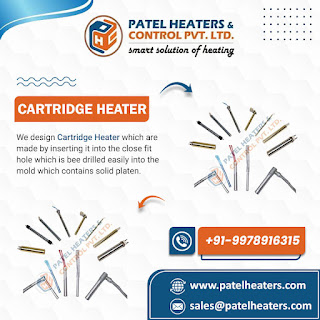

Brief Overview

A cartridge heater is a cylindrical electrical heating element that is widely used for heating various mediums in industries. It consists of a resistance wire, typically made from nickel-chromium or iron-chromium alloys, wound around a ceramic or metal core. This core is then encased in a protective sheath, often made of stainless steel. The compact design of these heaters allows for easy insertion into a variety of heating applications, including molds, dies, platens, and more.

Here are some of the benefits of using cartridge heater in your industry:

Precise and Uniform Heating

One of the primary benefits of using these heaters in industries is their ability to provide precise and uniform heating. The tightly wound coil design ensures even distribution of heat throughout the heating element, resulting in consistent temperature profiles. This precision is crucial in applications where temperature variations can negatively impact product quality or process efficiency. Industries such as plastics moulding, packaging, and semiconductor manufacturing rely on these heaters to maintain accurate and stable temperatures.

Versatility in Application

The heaters adaptability makes them suitable for a wide range of industrial processes. From heating liquid substances like oils and water to providing localized heating in machinery and equipment, these heaters offer a versatile heating solution. Their small size and high power density make them ideal for applications with limited space or when rapid heating is required. Industries such as aerospace, automotive, and electronics utilize these heaters for applications ranging from engine preheating to plastic extrusion.

Efficient Heat Transfer

These heaters are designed for efficient heat transfer, minimizing energy wastage and optimizing operational costs. The direct contact between the heater and the medium being heated ensures that the heat is quickly transferred, reducing the time required to reach the desired temperature. This efficiency not only improves production timelines but also contributes to energy savings, making these heaters an environmentally-friendly choice.

Customization Options

The ability to customize these heaters according to specific industrial requirements is another noteworthy advantage. Cartridge Heater Manufacturers in India are known for their expertise in producing tailor-made heating solutions. They offer a wide range of options including varying watt densities, sheath materials, mounting styles, and lead configurations. This customization ensures that the heaters seamlessly integrate into existing systems, enhancing their effectiveness and longevity.

Reliability and Durability

Industries demand heating solutions that can withstand harsh operating conditions and prolonged use. These heaters are renowned for their durability and reliability. The stainless-steel sheath provides excellent corrosion resistance, making them suitable for applications involving chemically aggressive environments. Additionally, their sturdy construction and high-quality materials enable them to perform consistently under demanding circumstances, reducing maintenance costs and downtime.

Indian Manufacturers and Exporters

India has a robust manufacturing sector that is known for its engineering expertise and high-quality products. For businesses looking to source these heaters globally, Indian Cartridge Heater Exporters offer a wide range of products to cater to diverse industry needs. These exporters have earned a reputation for delivering quality heating solutions to various corners of the world, contributing to India's presence in the global heating technology market.

Factors to Consider when using a Cartridge Heater

- The quality of the cartridge heaters: Make sure that the cartridge heaters you purchase are made from high-quality materials and are well-manufactured.

- The warranty: Make sure that the cartridge heater manufacturer or supplier offers a good warranty on their products.

- The price: Make sure that the cartridge heaters you purchase are priced competitively

Conclusion

The advantages of using these heaters in industries are abundant. From precise heating to versatility, efficiency, customization, and durability, these heaters have proven their worth in various industrial applications. By incorporating these heaters into their processes, industries can benefit from optimized operations, improved product quality, and cost savings – factors that are crucial in today's competitive market landscape. If you are looking around for this heater in India, you can contact Patel H

Comments

Post a Comment